With the advent of the Internet of Things, the key enabling technology in Industry 4.0 connects the entire value chain in the manufacturing industry through digital technologies.

Digital transformation and new technologies like intelligent SAP ERP Solutions – SAP S/4HANA powered by SAP Business Technology Platform (SAP BTP) have paved the path for intelligent machines that exchange information with each other and organize themselves. Manufacturing business processes across the entire value chain are connected and automated.

By linking the physical and digital manufacturing processes, production becomes more efficient, more flexible and more cost-effective.

This linkage gives rise to far-reaching changes both for companies and their employees. That is why the term Industry 4.0 stands for the fourth Industrial Revolution.

In this article, experts at VC ERP Consulting, one of the best SAP & Microsoft Gold Partner in India, help you understand –

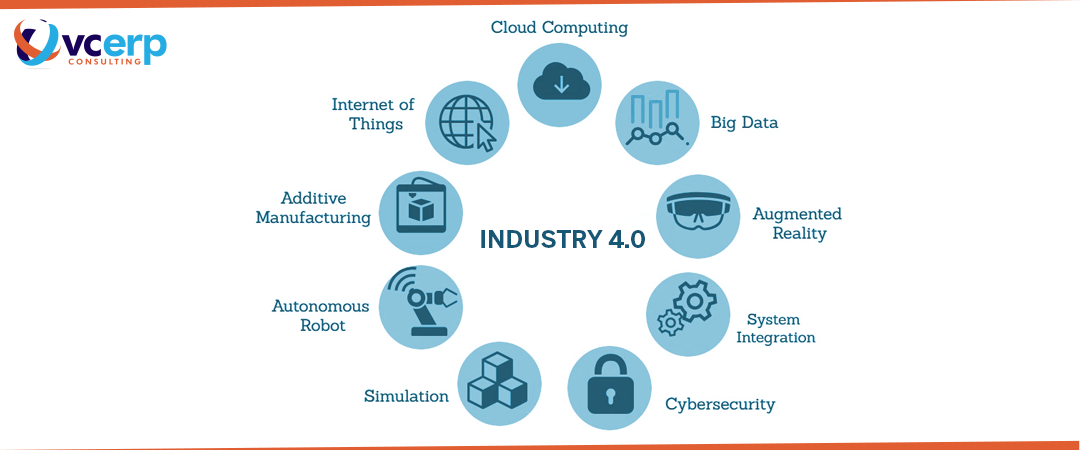

Industry 4.0 is the information-intensive transformation of manufacturing or related industries in a connected environment of big data, people, processes, services, systems and IoT-enabled industrial assets.

With the innovative twist of digital transformation & innovation of business processes you can –

Now that we have understood industry 4.0, let us see how it impacts manufacturing businesses.

According to statistics, the trend has picked up pace and that has been evident in the past years how manufacturing processes have changed fundamentally.

For instance, now machines can easily communicate via smart sensors – their sensory organs, they can collect mission-critical business data, which they pass on pre-filtered to a digitally linked platform.

This shapes the memory or brain. There, the machine data is merged with information from other sources, such as SAP ERP Solutions, SAP S/4HANA.

Moving on, once we are through with Industry 4.0, let us further get basic information about smart factories and their applications. Evolving consumer expectations are also giving rise to development of smart factory technologies and the factory of the future. Smart Factory solutions certainly minimize dependency upon overseas suppliers and manufacturers.

Evolving consumer expectations are also giving rise to development of smart factory technologies and the factory of the future. Smart Factory solutions certainly minimize dependency upon overseas suppliers and manufacturers.

Many traditional factories have been using automated devices and machines such as barcode scanners, cameras, and digitized production equipment in various parts of their operation.

These devices are not interconnected in traditional factories. The people, assets and data management systems in traditional factories all operate in isolation from one another.

Implement SAP S/4HANA with VC ERP Consulting, one of the best SAP Gold Partners in India and modernize your business processes.

How you begin your Smart Factory transformation totally depends on where your business is now and which processes are critical for your business. Initial audits will help you analyze and take a closer look at your existing processes, assets and business systems.

This is where VC ERP comes into the picture. Before we begin to automate workflows and manufacturing processes, we assess what they look like today.

Are you ready to bring Industry 4.0 to life? Get in touch with an award winning SAP Gold Partner, Certified Expert Consultants and Advisors at VC ERP Consulting for free consultation.

Call +91 7948998911 (India), Whatsapp +254 111229970 (Kenya), Call +1 469 915 6026 (North America) or drop an E-mail at sayhello@vc-erp.com

Digital transformation and new technologies like intelligent SAP ERP Solutions – SAP S/4HANA powered by SAP Business Technology Platform (SAP BTP) have paved the path for intelligent machines that exchange information with each other and organize themselves. Manufacturing business processes across the entire value chain are connected and automated.

By linking the physical and digital manufacturing processes, production becomes more efficient, more flexible and more cost-effective.

This linkage gives rise to far-reaching changes both for companies and their employees. That is why the term Industry 4.0 stands for the fourth Industrial Revolution.

In this article, experts at VC ERP Consulting, one of the best SAP & Microsoft Gold Partner in India, help you understand –

- What is industrial revolution four – industry 4.0

- How does it transform your manufacturing business processes

- What are Smart Factories, implications & benefits

The fourth Industrial Revolution – What is Industry 4.0?

Centralized Manufacturing controls are a thing of the past. Welcome to the smart factory!Industry 4.0 is used interchangeably with the fourth industrial revolution representing a new stage in your manufacturing business with increased control of the industrial value chain.Industry 4.0 is the information-intensive transformation of manufacturing or related industries in a connected environment of big data, people, processes, services, systems and IoT-enabled industrial assets.

With the innovative twist of digital transformation & innovation of business processes you can –

- Boost Profit Margins

- Optimize Business Costs

- Enhance Customer Experience

- Increase customer loyalty and lifetime value

- Grow and remain relevant with constant innovation

- Transport materials from point A to point B through factory halls with robots

- Easy flow of communication established between products and machines, which helps in making critical business decisions and initiate next production steps autonomously

- When devices need servicing, they automatically notify the service departments & much more

Now that we have understood industry 4.0, let us see how it impacts manufacturing businesses.

How does Industry 4.0 transform Your Business Processes?

According to the Statista survey “What is the significance of Industry 4.0 for your company?”, 62 percent of German companies already stated that they would be using special applications for Industry 4.0 in 2021.According to statistics, the trend has picked up pace and that has been evident in the past years how manufacturing processes have changed fundamentally.

For instance, now machines can easily communicate via smart sensors – their sensory organs, they can collect mission-critical business data, which they pass on pre-filtered to a digitally linked platform.

This shapes the memory or brain. There, the machine data is merged with information from other sources, such as SAP ERP Solutions, SAP S/4HANA.

Moving on, once we are through with Industry 4.0, let us further get basic information about smart factories and their applications.

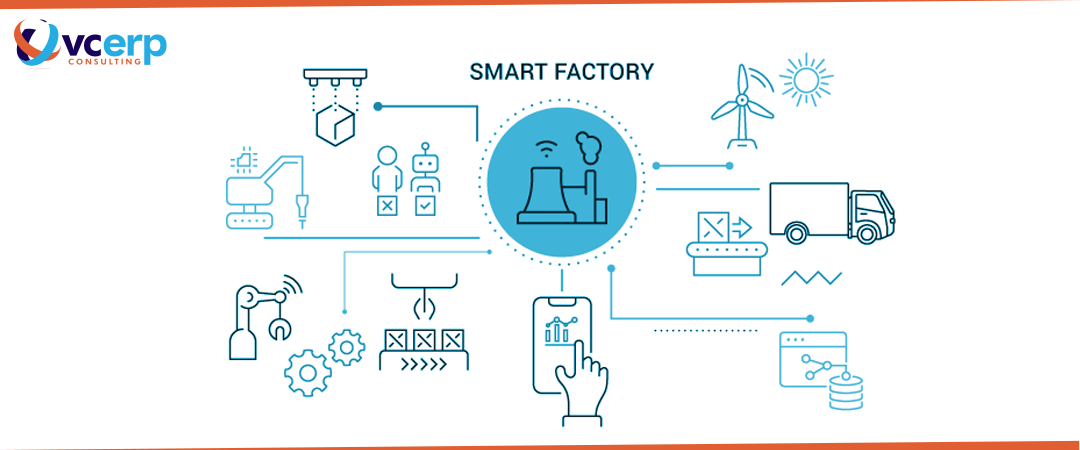

What is a Smart Factory & How does it Work?

Smart factories and smart manufacturing are part of the technological transformation known as Industry 4.0A Smart Factory is an interconnected network of machines, communication mechanisms and computing power. It is a cyber-physical system that uses advanced technologies such as artificial intelligence (AI) and machine learning to –- Analyze data

- Drive automated processes

- Learn as it goes.

Evolving consumer expectations are also giving rise to development of smart factory technologies and the factory of the future. Smart Factory solutions certainly minimize dependency upon overseas suppliers and manufacturers.

Evolving consumer expectations are also giving rise to development of smart factory technologies and the factory of the future. Smart Factory solutions certainly minimize dependency upon overseas suppliers and manufacturers.Smart Factory Solutions offered by VC ERP Consulting are as follows:

- SAP S/4HANA ERP Solution to optimize production processes

- Pave path towards smart inventories and digitize your warehouse operations with SAP Extended Warehouse Management

How does a Smart Factory Work?

Automated processes, smart devices and robotics are not unique to a smart factory – they have been in use for decades in manufacturing operations.Many traditional factories have been using automated devices and machines such as barcode scanners, cameras, and digitized production equipment in various parts of their operation.

These devices are not interconnected in traditional factories. The people, assets and data management systems in traditional factories all operate in isolation from one another.

Some of the many functions of Smart Factory are as follows:

- Integrate machines, data, people and assets into a single and digitally connected ecosystem

- Curate and analyze data by learning from experience with the help of Artificial Intelligence (AI)

- Interpret and gain insights from data sets to forecast trends and events

- Recommend and implement smart manufacturing workflows and automated processes

- Self-connect and self-optimize with continuous procedural improvement making itself and people more resilient, productive and safe

What are the Benefits of Smart Factory

According to Forbes magazine, in 2017 just 43% of manufacturers had smart factory initiatives underway. By 2019, 68% of them did.Manufacturing companies that invest in digital transformation and smart factory solutions, there is a strong potential for significant business benefits including –Improved Productivity and Efficiency

- Reduce the need of inactive practices and move supply chain management into a more resilient and responsive mode

- Use Predictive Analytics and Big Data analysis for optimized business processes

- Streamline your efforts and add to overall productivity of business operations by augmenting digital insights

- Smart Factories deliver:

- Just-in-time inventory management

- Accurate demand forecasting

- Improved speed-to-market

Sustainable and Safe Business Environment

International Society of Automation reports that robots and automated devices can help reduce or eliminate three out of the five leading causes for workplace injuries- Identify opportunities for more green, safe & socially responsible manufacturing practices

- Ensure irrefutable provenance and quality control of all materials and supplies – even when they are coming from the most distant links in the supply chain

- Source and manufacture products using socially and environmentally responsible methods

Enhanced Product Quality and Customer Experience

- Bring real-time insights and recommendations to all tiers of manufacturing process with cloud connectivity and complete visibility

- Rapidly customize and respond to shifting trends leading to tightly up to date products as per customer preferences

- Spot weakness or areas of improvement with advanced analysis of system data

- Improve competitiveness in the market, achieve better customer reviews and optimize costly returns or recalls

Implement SAP S/4HANA with VC ERP Consulting, one of the best SAP Gold Partners in India and modernize your business processes.

Deliver Breakthrough Business Value with ‘Smart Business’ Today!

Leverage the potential of your people, enhance staff skills and achieve competitive advantage with Smart Factory Solutions implemented by V ERP Consulting, one of the leading SAP & Microsoft Gold Partners in India.How you begin your Smart Factory transformation totally depends on where your business is now and which processes are critical for your business. Initial audits will help you analyze and take a closer look at your existing processes, assets and business systems.

This is where VC ERP comes into the picture. Before we begin to automate workflows and manufacturing processes, we assess what they look like today.

Are you ready to bring Industry 4.0 to life? Get in touch with an award winning SAP Gold Partner, Certified Expert Consultants and Advisors at VC ERP Consulting for free consultation.

Call +91 7948998911 (India), Whatsapp +254 111229970 (Kenya), Call +1 469 915 6026 (North America) or drop an E-mail at sayhello@vc-erp.com