“67% of manufacturers have accelerated digital transformation projects after COVID-19.” – 2021 Digital Transformation Assessment, IBM and The Manufacturer.Adopt intelligent ERP solutions by replacing legacy solutions and operations with digital transformation to enhance business performance. Many manufacturers have accelerated their digital transformation journey by deploying new technologies like –

- ERP Solutions

- Business Intelligence Solutions

- Sensors & Robotics

- Cloud Computing

- Industry 4.0

- IIoT technology

- The revolution of Industries from 1.0 to 4.0

- Impact of industrial revolution on businesses

- The VC ERP Consulting Approach for Industry 4.0

- Intelligent ERP for your Manufacturing business – SAP S/4HANA

- Taking functionality & customization to the next level with SAP Business Technology Platform (SAP BTP)

- Challenges to consider & overcome

- VC ERP Consulting Industry 4.0 offerings

- Introduction to SAP IIoT

- How VC ERP Consulting can help your manufacturing business

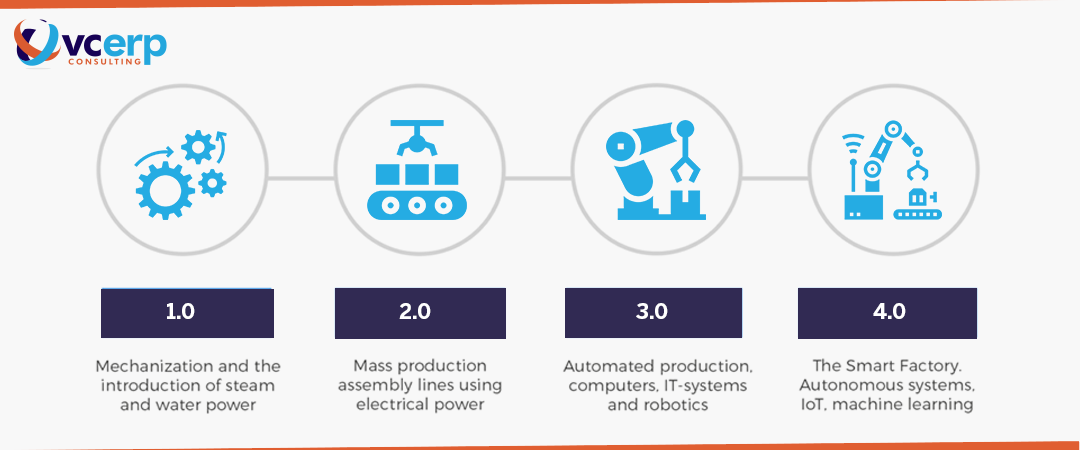

The Revolution of Industries from 1.0 to 4.0

Before diving deeper into the what, why, and how of Industry 4.0, it’s beneficial to first understand how exactly manufacturing has evolved since the 1800s. There are four distinct industrial revolutions that the world either has experienced or continues to experience today. Before going head first into how Industry 4.0 is relevant to your Manufacturing Business and how it directly ties into your revenue and profitability, let’s get up to speed with the other Industrial Revolutions that came before and their impact.The First Industrial Revolution

During the late 1700s and early 1800s, manufacturing evolved from focusing on manual labor to the use of water and steam-powered engines.The Second Industrial Revolution

In the early part of the 20th century, steel and the use of electricity in factories was introduced. Mass production concepts like assembly lines were introduced to boost productivity.The Third Industrial Revolution

Starting in the late 1950s, manufacturers began experiencing a shift that put less emphasis on analog and mechanical technology and more on digital technology and automation software.The Fourth Industrial Revolution

Industry 4.0 is the current industrial revolution that lies at the heart of digital transformation in manufacturing, automating processes and enabling real-time control.

The Impact of Industrial Revolution on Businesses

“Roughly one-fifth of the global workforce will be impacted by the adoption of AI and automation, with the most significant impact in developed nations like the UK, Germany and the US.” – A recent study released by McKinsey Global Institute.The fourth Industrial Revolution is largely driven by four specific technological developments:

- High-speed Mobile Internet

- AI & Automation

- The use of Big Data Analytics

- Cloud Technology.

The 4th Industrial Revolution has impacted nearly every industry. However, some industries share a higher likelihood of being the “early adopters” of advanced automation and technology.

At the top of the list ripe for Industry 4.0 technology revolution are use cases within the manufacturing sector across industries, especially, food preparation, construction, pharmaceuticals, life sciences, agricultural sectors and more.

VC ERP Consulting Solutions for Industry 4.0

We believe your manufacturing business can truly achieve the far-reaching benefits by leveraging the impact of industry 4.0. All a Business Leader needs is to be open to embracing technology holistically.SAP offers a broad solution portfolio for Industry 4.0 & as an SAP Gold Partner with 21+ years of expertise VC ERP Consulting implements these manufacturing solutions with demonstrated success.

This solution portfolio consists of –- Intelligent ERP SAP S/4HANA Cloud as the business backbone

- IntegratIon of SAP S/4HANA with SAP Business Technology Platform

- Cloud business applications

- To extend the existing ERP functionality using Industry 4.0 manufacturing scenarios

- To connect with devices in the factory

- SAP Internet of Things providing the data backbone with capabilities for –

- Smart Sensing

- Big Data Management

- Analytics & Intelligence

- Intelligent Edge Technology

- What about the challenges associated with incorporating new technologies and processes?

- Will my business be able to handle the implementation of these solutions?

Overcome Potential Manufacturing Business Challenges with VC ERP Consulting

Manufacturing businesses face numerous challenges. Some of the many burning business challenges faced by manufacturers are as follows –- Quality management in a constantly changing environment due to evolving customer demands

- Global competition and cost pressuring companies to constant optimize business operations

- Lack of visibility and capability to sense, predict and respond to disruptions

- Strict imposition of laws and regulations forcing companies to rethink their business processes

- Increases productivity, revenue and profitability

- Improves time-to-market and agility for customization of products

- Boosts productivity of assets and people

- Generate new revenue streams through business model innovations

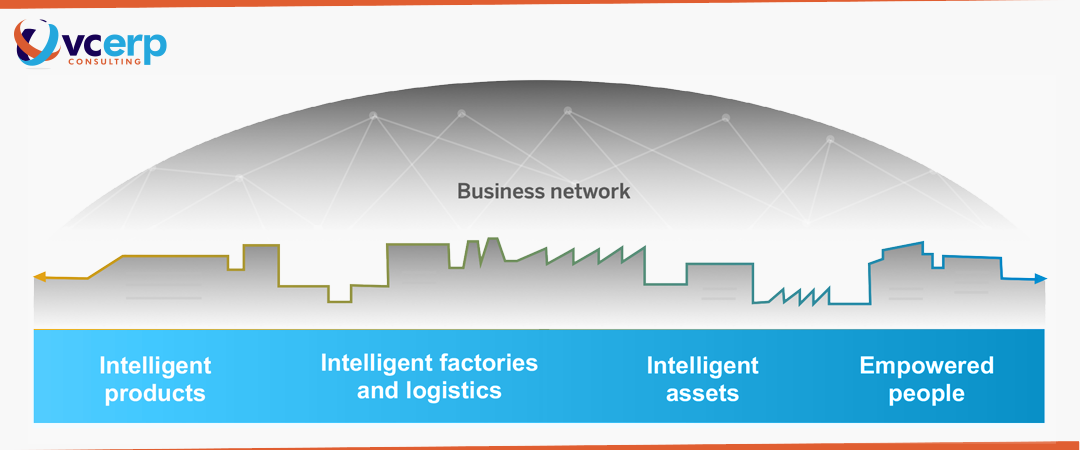

Industry 4.0 Solutions for your Manufacturing Business

Are you ready to transform your manufacturing business by implementing Industry 4.0 to increase productivity & customer satisfaction? Here are four winning strategic initiatives companies apply to embrace Industry 4.0.

Intelligent Products

Offer customized, sustainable, higher-quality products with Intelligent Products that are designed to meet customers’ unique configuration needs for maximized performance over time. Improve customer satisfaction, build strong brand loyalty and achieve a competitive edge in the market.Share information across your business from product quality and customer service to logistics and R&D. Anticipate service needs, receive remote upgrades and open the door to new, service-based business models.- Optimize production processes with SAP S/4HANA Manufacturing solution

- Address industrial IoT use cases with SAP Internet of Things (SAP IoT) solution

Intelligent Factories & Logistics

Today’s manufacturing environment is focused more on maximizing capacity and lowering cost. Respond quickly to changing customer needs and market dynamics while still controlling cost, capacity & quality with Intelligent Factories & Logistics. Use real-time data and artificial intelligence to run as autonomously and flexibly as possible with Intelligent Factories. Reduce operational cost, increase ability to deliver, improve asset performance and throughput, higher productivity, process efficiency and reduced risk.- Optimize production processes with SAP S/4HANA Manufacturing solution

- Digitize your warehouse operations with SAP Extended Warehouse Management

Intelligent Assets

Improve profitability, productivity, environmental and social outcomes with Intelligent Assets. Re-think your existing asset management approach and turn it into data-driven processes. Use contextualized insights derived from sensor and failure data to support better decision making.Monitor asset performance in real time, anticipate and prevent downtime, employ dynamic and predictive maintenance, take advantage of digital twins and tightly integrate assets and business processes.- Leverage IoT-enriched business insights to embed in and extend business processes with SAP Internet of Things (SAP IoT) solution

Empowered People

Manufacturing companies will always need people, no matter how far automation goes. Enable your people to manage complex tasks and unforeseen events with ad hoc decision support.These complex tasks become intellectually more demanding and require the right skills and information to make better decisions. Use IoT-enabled monitoring, geo-fencing and real-time analytics to improve health and safety.- Ensure the safety of employees and customers in times of change with SAP Environment, Health, and Safety Management

SAP Internet of Things

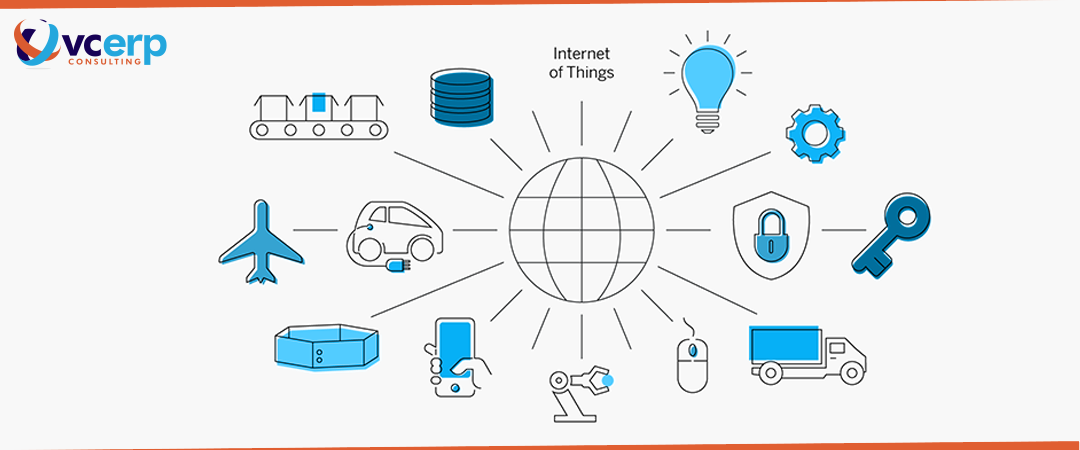

In the most basic terms, the Internet of Things includes any object – or “thing” – that can be connected to an Internet network, from factory equipment and cars to mobile devices and smart watches.

IoT devices are empowered to be our eyes and ears when we can’t physically be there. Equipped with sensors, devices capture the data that we might see, hear, or sense.

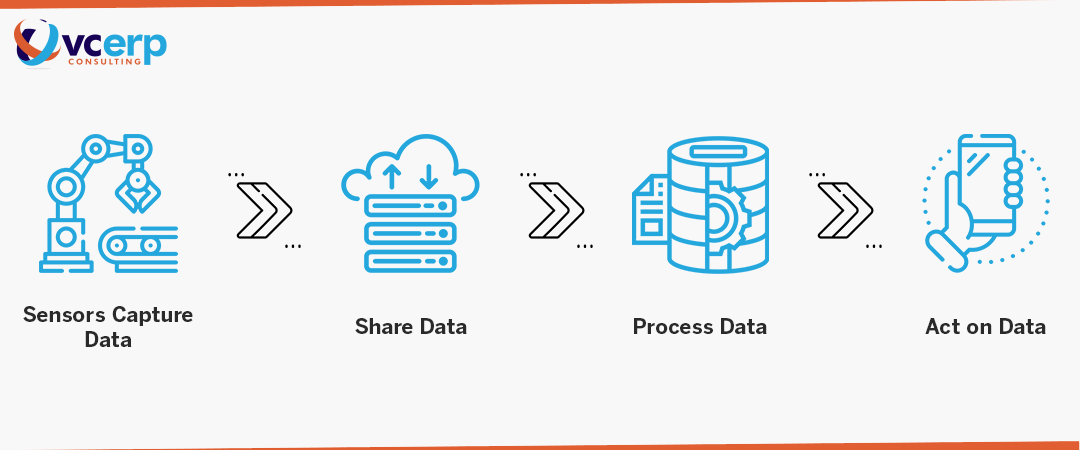

They then share that data as directed, and we analyze it to help us inform and automate our subsequent actions or decisions. There are four key stages in this process:

1. Capture the Data

IoT devices capture data from their environments through sensors. This could be as simple as the temperature or as complex a real-time video feed.2. Share the Data

Using available network connections, IoT devices make this data accessible through a public or private cloud as directed.3. Process the Data

At this point, software is programmed to do something based on that data – such as turn on a fan or send a warning.4. Act on the Data

Accumulated data from all devices within an IoT network is analyzed. This delivers powerful insights to inform confident actions and business decisions.

Implement SAP IoT with VC ERP Consulting to move your digitalization from factory focused

initiatives to a company-wide, competitive business strategy. Combine manufacturing automation with enterprise business information and execution.Transform your Manufacturing Business with VC ERP Consulting Today!

VC ERP Consulting offers an extensive portfolio to accelerate Industry 4.0 journey for your manufacturing business. We offer personalized and comprehensive support for your individual Industry 4.0 journeys. This helps business leaders to:- Explore and evaluate new business scenarios

- Define a strategic business vision

- Identify ways to improve current business scenarios through regular audits

- Develop a transformation roadmap and enable innovative business processes

Get in touch with award winning SAP Gold Partner, Certified Expert Consultants and Advisors at VC ERP Consulting for free consultation. Call +91 7948998911 (India), Whatsapp +254 111229970 (Kenya), Call +1 469 915 6026 (North America) or drop an E-mail at sayhello@vc-erp.com