Knowing that food is an important part of one’s life and overall well-being, your business is committed to manufacturing and processing high-quality products. However in the intricate world of food manufacturing, where every ingredient counts, the quest for operational excellence is an underrated struggle.

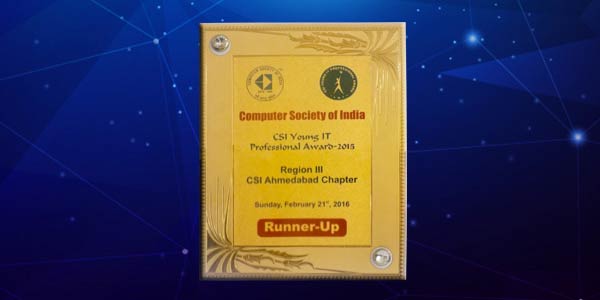

As an award-winning SAP Gold Partner with over two decades of industry expertise, we understand the unique hurdles faced by your business and unveil innovative solutions tailored to your specific needs. So if you’re wondering if your food industry business can leverage ERPs like SAP S/4HANA Cloud for manufacturing, look no further.

Today, we explore the transformative power of SAP S/4HANA Cloud with a taste of RISE with SAP, in addressing the diverse challenges faced by food manufacturing domains and discover how SAP S/4HANA Cloud stands as the beacon of efficiency in the face of adversity.

Which Food Manufacturing Domains Are Most Suitable for ERP Solutions?

If you’re wondering whether your Food Industry business can rely on technology-based solutions such as ERPs like SAP S/4HANA Cloud for the Food Manufacturing industry, you’re at the right place.

As an award-winning SAP Gold Partner with 22+ years of industry expertise, we understand first-hand the myriad challenges that your business encounters.

These food manufacturing domains are best suited to use SAP S/4HANA Private Cloud, RISE with SAP:

- Food and Beverages

- Packaged Foods, Namkeen & Snacks

- Ice Creams & Chocolates

- Soft Drinks & Juices

- Bakery & Baked Goods

- Dairy Products

- Edible Oil & Ghee

- Spices & Masala

- Tea Processors

- Packaged Drinks & Bottled Water

- Fresh Produce

- Sweets & Confectionery

The exact process of the final food product depends on your specific domain. However, ERP solutions such as SAP S/4HANA Cloud (RISE with SAP) support a variety of manufacturing processes from start to finish with industry standardization and business-specific customization.

What Are the Most Common Challenges Faced by Food Companies That ERP Can Solve?

The food industry is always growing, but it’s not without its challenges. From creating tasty new products to meeting strict safety standards, there’s a lot to consider. Plus, as we become more aware of climate change, we want our food to be produced sustainably.

Here are some of the challenges faced by the food manufacturing & processing industry including, but not limited to:

Complex Regulatory Compliance

Navigating strict standards for production environments and product quality.Real-Time Data Deficiency

Real-time data is the foundation of predictive and prescriptive analytics for making proactive decision-making and actions.Quality Control

Ensuring consistent product quality throughout the production process, from raw materials inspection to finished product testing.Temperature Control

Ensuring ideal storage, preservation and shipment of temperature-sensitive foods like meats, vegetables, dairy, eggs, and ready-to-eat foods.Production Variance Analysis

Analyzing actual production costs vs. expected costs to evaluate inventory management, production processes, and sales efficiency.Machinery Inefficiencies

Tracking equipment performance.Inefficient Warehouse Management

Managing the receipt, storage, and shipment of food material items in FIFO.Time-Consuming Production Planning & Scheduling

Efficient scheduling not only increases production time but also reduces cleanout efforts by managing ingredients with expiry dates, minimizing wait times between operations, and handling changeovers between products.Managing Multiple Locations

Each location will have a culture of its own – from government incentives to the local labour market and thus multi-location inventory management is an important challenge.Supply Chain Risks

Dealing with price fluctuations, shortages, disruptions, lengthening and complicating supply chains.Traceability and Recall Challenges

Ensuring accurate traceability of food items throughout the distribution process for tracking product origins and recall readiness.Packaging & Labelling Requirements

India’s food safety regulations mandate clear labelling, packaging materials, and nutritional information to ensure safety and prevent misleading products.Ingredient Sourcing

Sourcing and verifying ingredients is related to reducing costs and saving on direct material costs.Equipment Upgrades

Handling ageing assets and depreciation.Inventory Management Struggles

Managing stock efficiently.Perishable Products Challenges

While these are some of the most common challenges that a food manufacturing and processing company faces, it is also important to consider the key challenges of the perishable food supply chain.

- Poor temperature management limits the geographic reach of the product and increases the risk of spoilage.

- Power outages, insufficient farm connectivity, and inadequate transportation infrastructure are all common causes of unexpected delivery delays and decreased shelf life (expiry date management).

- Inadequate cold chain support jeopardizes product quality and safety.

Food manufacturing companies face complex challenges like data management, compliance rules, traceability, quality control, and inventory management. An efficient food manufacturing ERP software is vital for food manufacturers to meet market demands effectively.

Today, many corporations in the food and beverage industry follow the “lean inventory” process to increase the value of their stocks by identifying and eliminating waste through continuous improvement of manufacturing processes. Toyota Motor Corporation famously adopted this approach when it switched to a make-to-order method.

While lean inventory management is widely used in the industry, food and beverage manufacturers typically manufacture their goods based on demand planning or even produce and stock what they believe their customers might want.

SAP S/4HANA Cloud for Food Manufacturing and Processing Companies

This digital age is changing the way businesses function with its constant connectivity and information exchange through various platforms such as the Internet of Things (IoT) and social networks. This results in business processes and decisions being transformed.

A material planner at a food manufacturing company is responsible for a large number of materials and is confronted with numerous exceptions on a daily basis. They have to ensure that there is enough supply to meet demand and take prompt action in case of material shortages or other critical situations.

It is a fact that production and purchase managers encounter challenges while dealing with production planning and evaluation in traditional systems, which is often time-consuming and labour-intensive.

The key features and benefits of SAP S/4HANA Cloud, private edition for food companies are:

Compliance Without the Complications

Regulatory Compliance Management

Navigate the intricate web of compliance rules effortlessly. SAP S/4HANA Manufacturing solutions help you follow compliance rules. You can make plans for specific places. You can connect tasks to rules. This way, you stay on top of regulations. And guess what? It’s not complex at all.Predicting Tomorrow’s Needs, Today

Demand Forecasting

Think about your business needs. How about improving your supply chain? SAP S/4HANA Cloud can help. It offers many features. For example, the Distribution Curve and Demand Management. You can control product variants easily. Plan for many items without stress. This ensures that all your products reach the customers. Now, that will make them happy!Production Scheduling Made Efficient

Efficient Production Scheduling

Imagine controlling your manufacturing process smoothly. This is possible with SAP S/4HANA. It does more than match demand and supply. It makes the process efficient. Look at features like Capacity Maintenance, Capacity Evaluation, and Detailed Plans. They let you manage your production schedule effortlessly. Enhancing Visibility and EfficiencyMRP Cockpit

The MRP (Material Requirements Planning) Cockpit in SAP S/4HANA Cloud brings clarity to your operations. It offers a crystal-clear view of shortages, both within your organization and in the external supply chain. Plus, it gives you an accurate picture of your inventory across multiple plants. The best part? Real-time stock alerts keep you informed about your current stock situation.Culinary Symphony

Product Recipe or Bill of Materials (BOM)

SAP S/4HANA Cloud encompasses a Product Recipe, also known as a Bill of Materials (BOM) which is a detailed list specifying the ingredients and their quantities required to create a product. It enables automatic inventory adjustments and helps calculate manufacturing costs. It is useful in efficient food manufacturing, ensuring precise ingredient management, cost control, and operational ease.Mastering the Art of Recipe Development

SAP S/4HANA Recipe Development (RD) is an essential module for effective recipe management in the food and beverage industry. Key sub-modules within RD cater to various aspects of the process, ensuring precision and compliance:- Recipe Management

- Ingredient Management

- Formula Management

- Label Management

- Recipe Analytics and Reporting

The food manufacturing industry is being transformed by SAP S/4HANA. This SAP ERP solution is making operations more efficient, reducing the need for manual processes and allowing workers to use mobile devices like smartphones and tablets to get things done.

RISE with SAP Use Cases

Optimizing Supply Chain Efficiency

In a bustling city, a leading chain of ready-to-cook meals and snacks faced the challenge of managing over 150 stores with standardized operations, each processing more than 1 million real-time transactions daily.

Seeking resilience and unified operations, the company embraced SAP S/4HANA Cloud. The deployment empowered the deli chain to enhance supply chain management efficiency, reconfigure core supply chain data, and adopt lean production practices.

In a mere nine months, the cloud-based solution streamlined production, distribution, and inventory management activities, ensuring same-day orders, production, and delivery. The result? Improved efficiency, lower IT costs, and the ability to evolve in a dynamic e-commerce landscape.

Building Business Resilience

Imagine a family-owned food company facing challenges to digitalize operations and promote economic growth. By choosing SAP S/4HANA Cloud through RISE with SAP,

- The company consolidated systems, achieving a 360-degree view of its operations.

- Leveraged the real-time analytics provided by SAP HANA to optimize inventory levels, manage suppliers effectively, and gain insights into sales and research and development.

- This reduced IT costs by 10%, while enhanced efficiency, visibility, and productivity supported the planned expansion.

From Recruitment to Retirement

Imagine a food industry company undergoing a digital transformation journey. Their HR systems are in dire need of streamlining, and the hiring process is tedious and often prone to system failures. That’s where SAP SuccessFactors comes in, revolutionizing HR processes from recruitment to retirement.

With the SAP Business Technology Platform, custom extensions enable efficient handling of high-volume hiring during seasonal surges. Automation takes the spotlight, reducing hiring processing time by up to 90% in some markets. Additionally, a multilingual chatbot serves as a game-changer, providing a seamless experience for thousands of candidates.

Enhanced Business Network for Procurement:

A food manufacturer aims to strengthen its procurement process by seamlessly connecting with suppliers, carriers, and other partners. With RISE with SAP’s SAP Business Network Starter Pack, the company can

- Qualify suppliers easily

- Manage inventory

- Improve transparency in the source-to-pay process

- Efficiently tracks stock in transit

- Performs analytics for better decision-making

- Ensures transparent collaboration with suppliers Flexible System Hosting Options:

Why VC ERP Consulting?

SAP S/4HANA Cloud is your ticket to simplifying and accelerating your transition to the cloud and achieving continuous innovation. But with so many options and partners available, who can you trust to guide you through this pivotal transformation? Enter VC ERP Consulting – your dedicated and experienced partner on this journey.

VC ERP Consulting stands at the forefront of SAP’s cloud transformation. Our commitment to customization ensures your organization’s unique needs are met, whether you’re just beginning your cloud journey or managing a complex multi-cloud environment. We understand the intricacies of open source, APIs, and microservices, allowing us to help you navigate the challenges of these technologies and implement agile processes.

When selecting an implementation partner for SAP S/4HANA Cloud, look for industry-specific expertise, implementation experience, and customization capabilities – VC ERP Consulting offers all of these and more.

VC ERP Consulting’s SAP Capabilities include:- Digital Transformation Services

- Business Transformation As a Service

- Value & Impact Assessment

- Process Audit & Improvisation

- System Administration & Maintenance

- SAP S/4HANA Implementation

- Rollouts – Patch Upgrades

- Localization

- Technical Migration

- Data Migration

- Testing

- SAP Application Management Services

Are you ready to embrace innovation, efficiency, and business excellence with RISE with SAP? Reach out to our experts at VC ERP Consulting, your trusted SAP Gold Partner, to shape the future of your growing business.

Contact Us Today!

– WhatsApp +254 111229970 (Kenya)

– Call +91 7948998911 (India)

– Call +1 469 915 6026 (North America)

– Call +974 31239246 (MENA)

– Email: sayhello@vc-erp.com